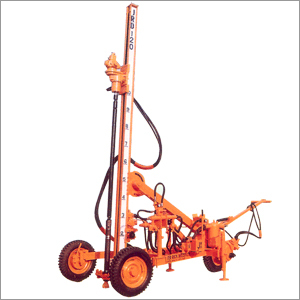

Wagon Drill

Product Details:

- Spindle Speed Variable (Depending on Model)

- Diameter 32 to 100 mm

- Machine Type Wagon Mounted Drilling Machine

- Frequency 50 Hz

- Cutting Area Adaptable to site requirements

- Condition New

- Noise Level Standard Industrial

- Click to view more

Wagon Drill Price And Quantity

- 650000 INR/Unit

- 1 Unit

Wagon Drill Product Specifications

- Approx. 500 kg

- Blast hole drilling, mining, quarrying, construction

- 5 HP

- Standard Industrial

- Electric

- Up to 100 mm diameter holes

- 5 HP

- Yellow

- No

- 415 V

- New

- 50 Hz

- Manual

- Adaptable to site requirements

- 32 to 100 mm

- Wagon Mounted Drilling Machine

- Variable (Depending on Model)

- No

- Mild Steel

- 2100 x 900 x 1000 mm

- Wagon Drill

Wagon Drill Trade Information

- Paypal, Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Telegraphic Transfer (T/T), Days after Acceptance (DA)

- as per the requirement Days

- Australia, South America, Middle East, Western Europe, Africa, Central America, Asia, Eastern Europe, North America

- All India

Product Description

Wagon Drill JRD-120 (DTH)

Wagon Drill JRD-120 capable of drilling 76-115mm Dia holes to a depth of 36.5mtrs by DOWN-THE-HOLE technique used in open cast mines for drilling and blasting purposes. The Drill is mounted on rugged box frame, fitted on wheels for easy shifting from hole to hole can drill holes from vertical to horizontal. The drill is fitted with 4.5 H.P. Rotation Unit, 4.5 H.P. Feed unit, 6 H.P. Self propulsion Units. The Rig is supplied with pressure Hoses, Control Valves and Air Line Lubricator. The drills are available to handle 76mm Dia X 2mtrs (6ft) & 3mtrs (10ft) drill pipes.

Special Features:

Stable Drilling capabilities

Structrals designed for extra rigidity

Base frame in box constructions

Anchoring arrangement ensures perfect stability during drilling

Rear wheel swivelable by 90 degrees to prevent movement during toe hole drilling

Effectively braked wheels with telescopic adjustable in the front holding the unit firmly

Easy manoeuvrability both in manual and self propulsion modes

Specially designed fluid seals to prevent air leakages

Ergonomically placed controls for both drilling and tramming operations to ensure ease of operation which reduces operator fatigue

| HOLE RANGE: | |

| Down the hole Air Hammer (DTH) | Dia76mm ~ Dia115mm |

| Drill Pipe (for Drill Bit DIA 90mm to 115mm) | 76mm O.D X 3mtrs. long Length |

| Drill Pipe (For Drill Bit DIA76mm) | 60.3mm O.D X 1.5mtrs. long Length |

|

|

|

| Rotation Unit for DTH: | |

| BHP | 4.5H.P |

| Speed | 0~50 RPM |

| Torque | 1125Nm (10,000 lb.in) |

|

|

|

| Feed Unit: | |

| BHP | 4.5H.P |

| Pull up Force | 0~2200 kgf |

| Pull Down Force | 0~2200 kgf |

| Max Pull up Speed | 0~15m/min |

| Feed Type | Chain |

|

|

|

| Propulsion/Traction Motor | |

| Pneumatic Wheel Drive Motor | Air Motor with Self Braking Gearbox |

| Air Motor Power | 4.5/6.0H.P |

| Tramming Speed | 1.5 Km/hr |

|

|

|

| Recommended Air Compressor Capacity: | |

| For Down the hole Air Hammer (DTH) |

|

| Free Air Delivery | 450CFM (12.7m3/min) |

| Working Pressure | 150PSI (10.5kg/cm2) |

|

|

|

| Dimensions & Weight |

|

| Over All Length | 4960mm |

| Over All Width | 2040mm |

| Height | 900mm |

| Total Weight | 1250Kgs |

Versatile Drilling Power

Suited for mining, construction, and quarrying, the Wagon Drill delivers efficient blast hole drilling with adaptable cutting area and variable spindle speed. Its 5 HP motor and rugged mild steel construction make it perfect for demanding industrial environments, giving you the flexibility to drill holes from 32 mm up to 100 mm in diameter.

Built to Last and Easy to Use

This wagon-mounted machine boasts a solid manual control system, making operation straightforward and maintenance hassle-free. Its thermally protected electric motor and standardized design offer durability and resilience, facilitating consistent performance across diverse worksites.

FAQs of Wagon Drill:

Q: How does the Wagon Drill operate on site?

A: The Wagon Drill operates by being manually controlled and powered through a 5 HP electric motor at 415 V. It is designed to move easily on-site with its wagon-mounted base, allowing you to position it at various blast hole drilling locations in mining, quarrying, or construction environments.Q: What are the main usage and applications of this Wagon Mounted Drilling Machine?

A: This drilling machine is primarily used for blast hole drilling in mining, quarrying, and construction projects. Its adaptable cutting area and capacity to drill holes between 32 mm and 100 mm in diameter make it suitable for a variety of drilling tasks required in these industries.Q: When should I use a manual Wagon Drill over an automated or CNC drill?

A: A manual Wagon Drill is preferred when you require straightforward operation, adaptability to varying site conditions, and cost-effectiveness. It is ideal for environments where computerized or CNC systems are not feasible, offering reliable manual control and maintenance simplicity.Q: Where can the Wagon Drill be effectively deployed?

A: The Wagon Drill can be deployed in open mining sites, quarries, and large-scale construction areas. Its mobility and adaptable cutting area make it practical for shifting between different locations within these large operational sites.Q: What is the drilling capacity and maximum hole diameter the machine can handle?

A: The Wagon Drill is capable of drilling holes with diameters ranging from 32 mm to 100 mm, catering to blast hole requirements in a range of site-specific conditions and rock types.Q: How does using this Wagon Drill benefit industrial operations?

A: This wagon-mounted drill machine offers robust construction, flexibility in drilling dimensions, and ease of manual operation. Its durability and operational efficiency reduce downtime and enhance productivity in mining, quarrying, and construction projects.Q: What is involved in the setup and operation process for this drilling machine?

A: Setting up this Wagon Drill typically involves positioning the machine on the chosen site, connecting it to an appropriate 415 V power supply, and manually adjusting controls to the desired spindle speed and cutting area. Operation is then managed manually, ensuring direct and responsive control during drilling tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese